Site

-

- BASF Zhanjiang Verbund Site

-

- BASF Integrated Site (Guangdong) Co. Ltd.,

- Predominantly Chemicals Operations

- Guangdong

- No. 300, Gangnan Avenue, Zhanjiang Economic and Technological Development Zone.

-

- #SI1184

Description

Insights from our Experts

|

2026/01/17 11:10 AM

BASF's Zhanjiang ethylene plant | Source: Sina Finance (Jan 8, 2026) BASF has successfully commissioned the 1 million tonnes per year ethylene plant at its newly built |

| Indicator | Unit | Value | |||

|---|---|---|---|---|---|

|

Data Transparency | True | 1 | ||

|

Modelling Status | True | 1 |

Content provided by

| Transaction | Name | Date |

|---|---|---|

| Modified by |

|

1/17/2026 10:07 AM |

| Added by |

|

12/13/2024 12:56 PM |

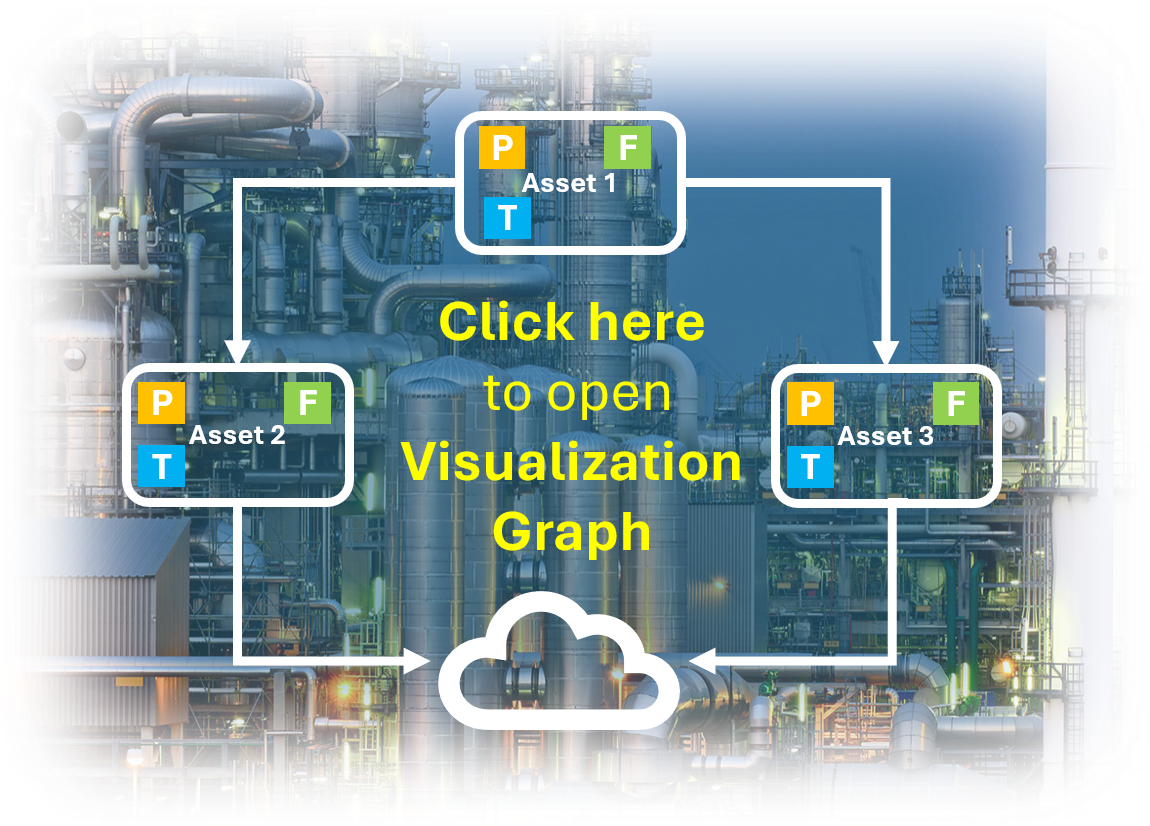

Dashboard

| Chart Creators | Date | |

|---|---|---|

| Modified by |

|

1/17/2026 10:44 AM |

| Created by |

|

12/13/2024 12:56 PM |