Sinopec Hunan Petrochemical Caprolactam New District; Credit.

3rd Apr 2015: Baling Petrochemical Company was established

Baling Petrochemical is a large petrochemical complex with a history of more than 40 years, integrating oil, chemicals, fiber and fertilizer. The facility is part of a larger petrochemical complex that includes:

- Original Yueyang Petrochemical Plant

- Dongting Nitrogen Fertilizer Plant

- Yingshan Petrochemical Plant

9th Nov 2016: SINOPEC Hunan Company

After 40 years of development, Baling has become an extra-large scale petrochemical complex starting from crude refining to the integrated operation and production of petrochemicals, chemical fibers and fertilizers. As the largest domestic manufacturer of SBS, epoxy resin, caprolactam and commercial cyclohexanone, Baling produces more than 160 products, including gasoline, diesel, diluents, cyclohexanone, SBS, epoxy resin, caprolactam, urea, etc., with trade marks including “Baling”, “Furong”, “Yingwang” and “Bairong” respectively. The total output is approximately 4 millions tons per year, with over RMB30 billion of sales revenue.

25th Jan 2021 (last updated): China Petroleum & Chemical Corporation Baling Branch

Sinopec Baling Branch, located in Yueyang City , Hunan Province , is a large-scale petrochemical complex with oil refining as its leading factor and integrating oil, chemical fiber and fertilizer. It is also the largest production base of SBS, epoxy resin, caprolactam and commercial cyclohexanone in China. Its main products include more than 160 kinds of gasoline, diesel, diluent, cyclohexanone, SBS, epoxy resin, caprolactam, urea, etc. It has registered the trademarks of "Baling", "Furong", "Yingwang" and "Bairong", with an annual product volume of 4 million tons and sales revenue of 18 billion yuan.

It has independently developed production process technologies such as 100,000 tons/year cyclohexanone, 200,000 tons/year SBS, 140,000 tons/year caprolactam and 20,000 tons/year SEBS. It has 176 authorized patents and has won nearly 50 national, provincial and ministerial science and technology progress awards. The "cyclohexanone ammoximation project" has been included in the national key basic research and development planning projects; lithium polymer "SEBS complete set technology development" and "bionic catalytic oxidation to produce cyclohexanone" and other projects have been included in the national "863" plan.

30th Jul 2023: Baling Petrochemical and Changling Refining and Chemical officially entered the merger implementation stage

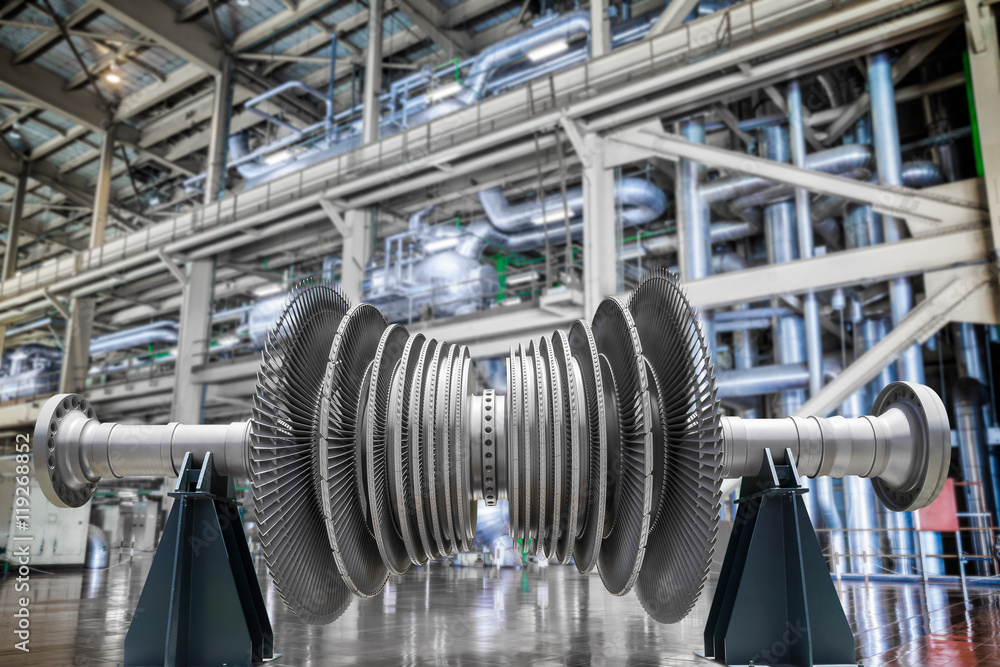

Baling Petrochemical has a comprehensive refining capacity of 2 million tons per year, mainly including five product chains: refining, synthetic rubber, epoxy resin, caprolactam, and coal chemical industry. In early July, the expansion of the lactam production capacity of Baling Petrochemical from 300,000 tons to 600,000 tons and the relocation of the caprolactam industry chain were successfully completed, making it the largest caprolactam production base in China, marking the further development of Baling Petrochemical towards the goal of becoming a global high-quality chemical company.

15th Dec 2023: Baling Petrochemical

On December 15, 2023, Line A of Baling Petrochemical's 600,000 tons/year caprolactam industry chain relocation and upgrading transformation and development project was completed and successfully started up at one time, marking the completion and production of the world's largest single-unit caprolactam production and research and development base with leading technology, opening up a new path for the green transformation and development of heavy chemical industry along the river.

The project adopts Sinopec's new generation of caprolactam green complete set of new technologies with independent intellectual property rights, and realizes industrial application for the first time. The project construction includes 58 sets of new coal gasification, caprolactam, polyamide, synthetic ammonia, hydrogen peroxide, cyclohexanone and other equipment, covering the entire industrial chain from coal-to-hydrogen to polyamide, with a localization rate of 99.9% of the equipment, including the central control system, which is completely localized.