Braskem's Operations at the Duque de Caxias Petrochemical Complex | Credit: C. Moutinho (May 27, 2024). O Patrononews

The Braskem Duque de Caxias petrochemical complex is located in Duque de Caxias, Rio de Janeiro state, Brazil, approximately 32 km northwest of Rio de Janeiro city. The complex represents one of Braskem's integrated manufacturing hubs in Brazil, producing olefins and polyolefins for domestic and export markets.

Historical Background

The Duque de Caxias complex traces its origins to the consolidation of Brazil's petrochemical industry. Braskem was formed in August 2002 through the integration of six companies: Copene, OPP Petrochemical, Trikem, Proppet, Nitrocarbono, and Polialden. The Rio de Janeiro assets, including the Duque de Caxias site, were part of OPP Petrochemical (Organização Odebrecht de Petroquímica e Plásticos), which Odebrecht had incorporated in 1995.

Current Configuration

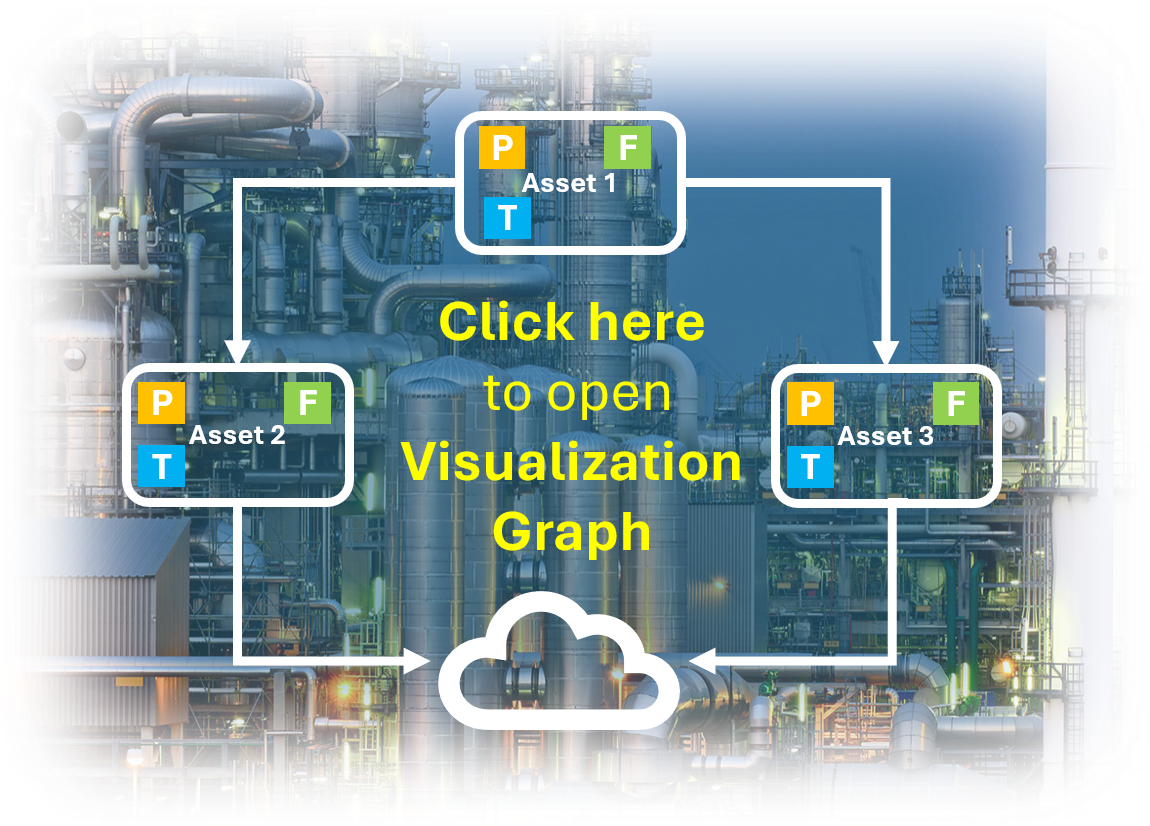

The Duque de Caxias site currently houses three Braskem industrial units (go to assets descriptions for confirmation details):

| Unit |

Full Name |

Technology |

Licensor |

Capacity (kt/yr) |

Startup |

Certifications |

| UNIB4 DCX |

Cracker Unit 4 Duque de Caxias |

Steam cracking |

ABB Lummus Global, now Lummus Technologies |

520 ethylene |

2004 |

ISO 9001 |

| PE9 DCX |

Polyethylene Unit 9 Duque de Caxias |

UNIPOL™ PE (2 gas-phase reactors) |

Univation Technologies |

540 (270 HDPE + 270 LLDPE) |

2004 |

ISO 9001 |

| PP5 DCX |

Polypropylene Unit 5 Duque de Caxias |

UNIPOL™ PP (gas-phase) |

Univation Technologies,

now W.R. Grace

|

310 |

2004 |

ISO 9001, ISO 14001, OHSAS 18001 |

The complex employs over 1,400 workers and contractors and maintains 122 local suppliers, with R$80 million invested annually in regional hiring and services.

Feedstock Integration and Strategic Investments

Braskem has invested in feedstock flexibility at the Duque de Caxias site. In late 2017, the complex received its first ethane shipment from the United States—4,500 tonnes of shale gas-derived ethane from Enterprise Products—as part of a strategy to diversify raw material sources and improve cost competitiveness.

The approved 2025 expansion project will add a new ethane cracking furnace and polyethylene capacity, supported by a long-term ethane supply agreement with Petrobras. Ethane will be sourced from Petrobras' Boaventura Complex (Natural Gas Processing Unit) in Itaboraí, RJ, and delivered via the Rota 3 pipeline infrastructure.

Environmental and Sustainability Performance

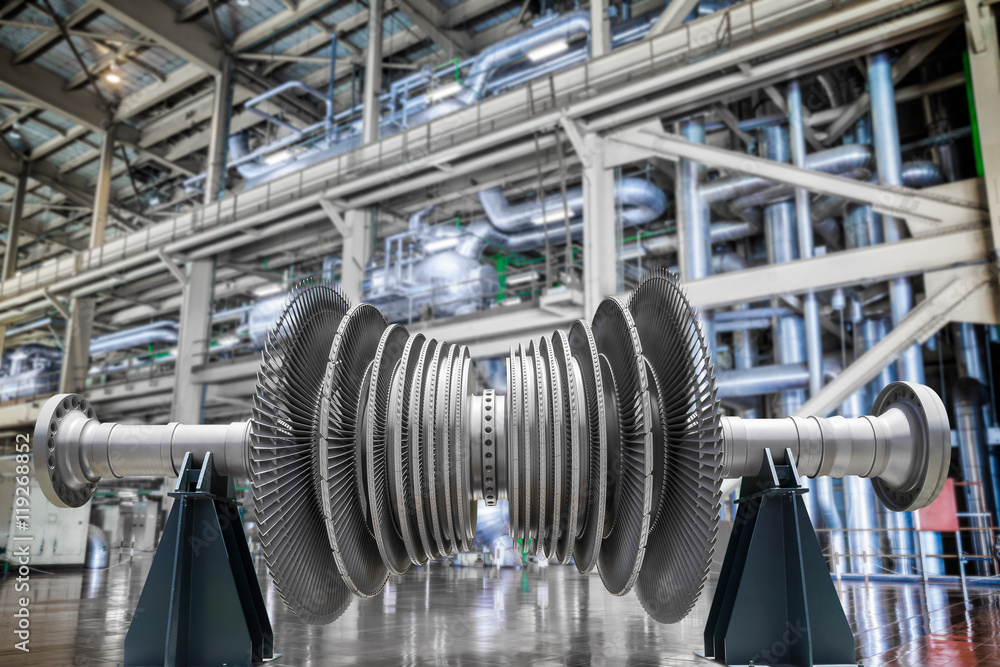

The Duque de Caxias complex operates under Brazilian environmental regulations and has received investment in water, energy efficiency, and emission reduction. Recent initiatives include energy optimization through Real-Time Optimization (ERTO) systems at the Q4 cracker and electrification projects to replace steam turbines with high-efficiency electric motors powered by cogeneration plants.

Market Role and Strategic Importance

The DCX complex supplies polyethylene and polypropylene resins to key Brazilian markets including packaging, automotive, construction, and consumer goods. Its proximity to Rio de Janeiro and São Paulo—Brazil's two largest industrial centers—provides strategic logistics advantages for domestic distribution. The site also supports export volumes to Latin American markets.

The approved expansion reinforces Braskem's commitment to the Brazilian market and positions the complex as a competitive, gas-advantaged manufacturing hub aligned with the company's energy transition and decarbonization goals.