Site

-

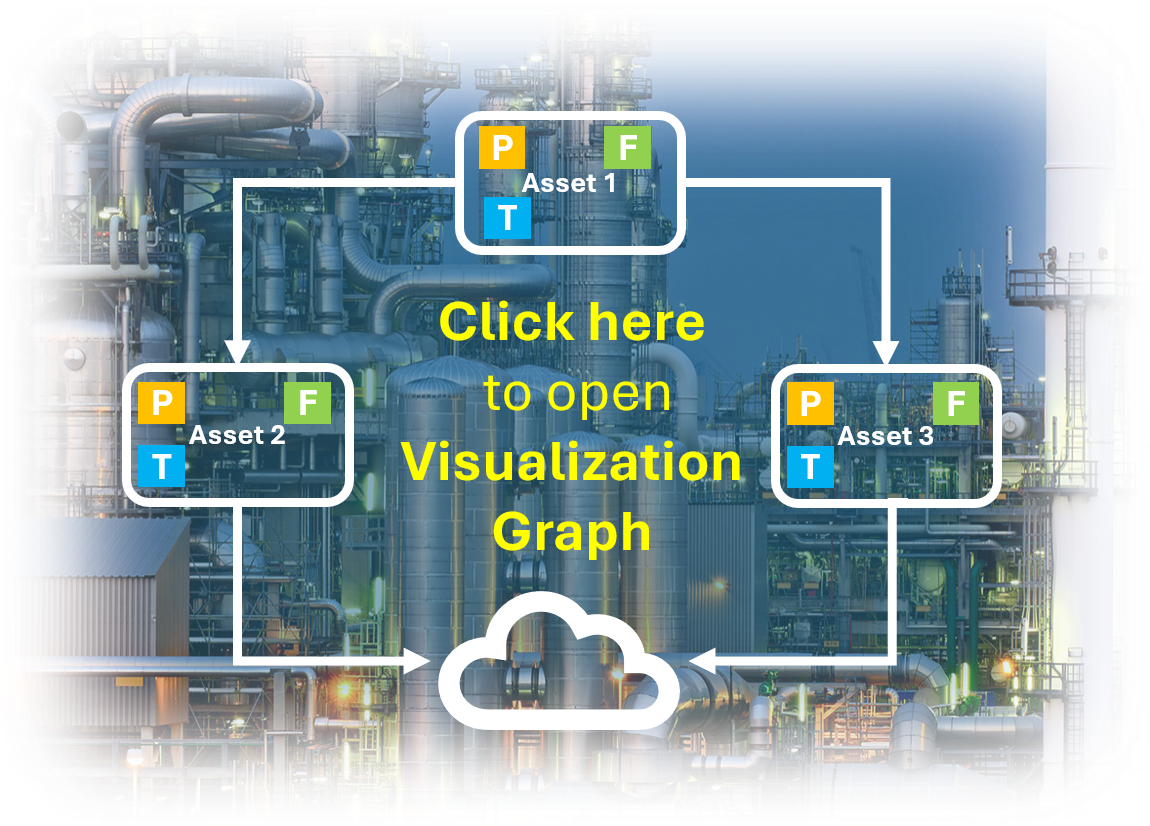

- HPCL Rajasthan Refinery

-

- HPCL Rajasthan Refinery Limited

- Site in a Project-Phase

-

/ Barmer

- 342014

- Rajasthan

- Sambhra, Pachpadra

-

- #SI797

Description

Your insights will be shown here

| Indicator | Unit | Value | |||

|---|---|---|---|---|---|

|

Modelling Status | True | 1 |

Content provided by

| Transaction | Name | Date |

|---|---|---|

| Modified by |

|

10/7/2025 4:50 PM |

| Added by |

|

3/4/2023 6:48 PM |

Dashboard

| Chart Creators | Date | |

|---|---|---|

| Modified | 6/1/2025 9:41 AM | |

| Created by |

|

5/26/2025 12:19 PM |