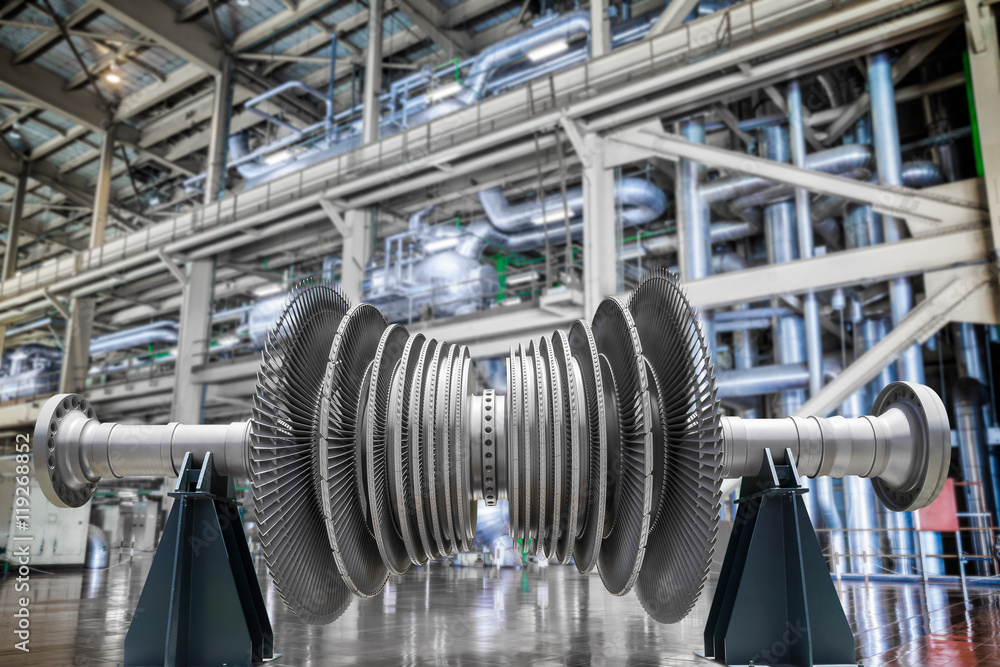

ZapSibNeftekhim Petrochemical Complex in Tobolsk (Aug 2021) | Credit: Oil&Gas Journal

ZapSibNeftekhim LLC operates Russia's largest integrated petrochemical site in Tobolsk, Tyumen Region, approximately 10 km east of the city. Following a 2020 merger with SIBUR Tobolsk LLC, the company manages the entire Tobolsk petrochemical cluster, converting associated petroleum gas and natural gas liquids from Western Siberian fields into high-value polymers and petrochemical products.

Feedstock Processing & NGL Fractionation

The complex receives wide-fraction light hydrocarbons (NGL) via product pipeline from Western Siberian gas processing plants operated by SIBUR and other companies processing associated petroleum gas. The NGL processing plant (CGFC) has a capacity of 8 million tons per year, separating feedstock into propane, butane, isobutane, and other fractions for downstream processing or direct shipment to customers.

Olefins Production (Steam Cracking)

The world-scale pyrolysis complex, commissioned in 2019, produces 1.5 million tons of ethylene and 500,000 tons of propylene annually, plus 240,000 tons of high-margin co-products (butadiene, butene-1, MTBE, pyrogasoline). This is currently Russia's only ethylene plant of this scale and ranks among the top five globally.

Key equipment specifications:

- Nine pyrolysis furnaces (eight operating, one spare): 60 meters high, 2,600 tons each, operating at 850°C

- Pyrogas compressor: 82 MW capacity (111,500 horsepower)

- Propylene distillation column: 106 meters high, 6.5 meters diameter, 917 tons

- Ethylene distillation column: 64 meters high, 6.5 meters diameter, 501 tons

Polyethylene Production

Capacity: 1.5 million tons per year

The complex operates four polymerization units using INEOS technologies commissioned in 2019-2020:

- Two slurry units (Innovene S): 43.7 tph each (700,000 tpa combined) producing HDPE

- Two gas-phase units (Innovene G): 50 tph each (800,000 tpa combined) producing LLDPE and bimodal HDPE

Five extrusion lines process polymer into granules: four for natural-color products and one dedicated line for pipe-grade PE100 with carbon black additive. The extrusion building stands 110 meters tall, equivalent to a 37-story building.

Polypropylene Production

Total capacity: 1 million tons per year - Russia's largest PP capacity

Two installations operate with different technologies:

- Innovene PP unit (INEOS): 500,000 tpa, commissioned 2013 at legacy SIBUR Tobolsk facility

- Spheripol unit (LyondellBasell): 500,000 tpa, commissioned 2019 as part of ZapSibNeftekhim project, with one polymerization line and two parallel extrusion lines (40 tph each)

Monomer & Derivatives Production

Additional processing units include:

- Butadiene production: 207,000 tpa

- Isobutylene production: 202,000 tpa

- MTBE production: 155,000 tpa

- Propane dehydrogenation (PDH): 510,000 tpa propylene

- Maleic anhydride plant (under construction): 45,000 tpa

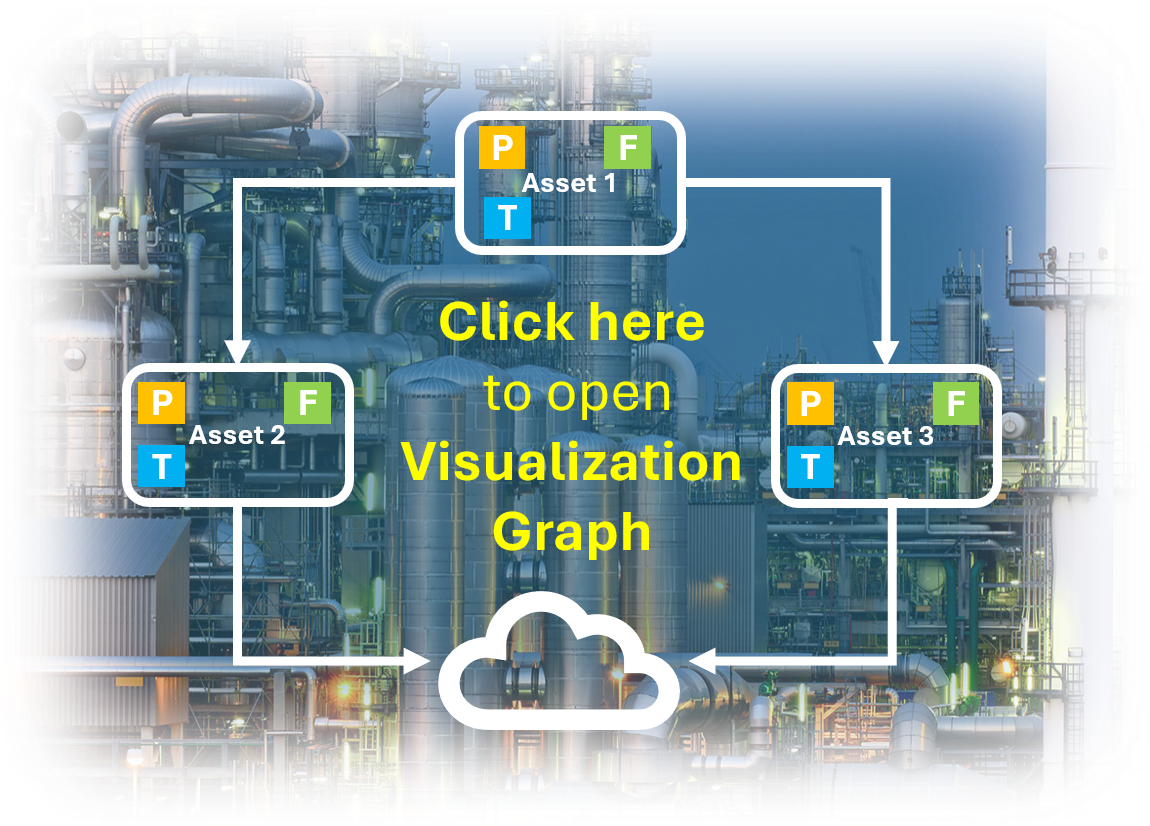

Energy Infrastructure

The integrated energy complex provides self-sufficient power and heat generation:

Electric, Thermal and Steam Generation (ETPG) facility:

- Electric capacity: 665.3 MW

- Thermal capacity: 2,223 MW

- Equipment: Five steam turbines, nine power boilers, three peak hot water boilers

- Fuel: Natural gas from Urengoy-Chelyabinsk pipeline via gas distribution station; fuel oil as backup

- Grid connection: 220 kV and 110 kV to unified Russian power system; 10 kV for internal distribution

The ETPG facility also supplies heat to Tobolsk city's residential and social infrastructure.

Auxiliary utilities:

- Nitrogen-oxygen production (ACP)

- Water supply and sewerage (VIC)

- Industrial wastewater neutralization and treatment (NOPSV)

- Heat, gas supply and interdepartmental communications (CTGSiMCC)

Logistics Platform

The logistics infrastructure spans 38.8 hectares with comprehensive storage, packaging, and shipment capabilities:

- Finished product warehouse: 12 hectares, 42,000 tons storage capacity

- Packaging lines: Eight mobile FFS machines processing 2,200 bags/hour each (440 tons/hour total in 25 kg bags)

- Bulk loading: Six machines at 90 tons/hour for container shipment

- Container platform: Four cranes (36-ton capacity), storage for 2,400 forty-foot containers, approximately 200 containers shipped daily

- Vehicle processing: Infrastructure for 270 trucks with receiving, processing, and distribution to warehouses

The complex serves both domestic Russian markets and exports to Europe and Asia via rail and containerized shipment from the Denisovka railway station.

References

- SIBUR International. (2019, October 17). ZapSibNeftekhim produces first polyethylene from its own feedstock. Retrieved from https://sibur-int.com/press/news/item3767.php

- SIBUR International. (n.d.). Polypropylene and polyethylene product catalog - ZapSibNeftekhim. Retrieved from https://sibur-int.com/upload/basic-polymer-current-zapsibpr.pdf

- SIBUR International. (n.d.). Polypropylene and polyethylene product catalog - ZapSibNeftekhim. Retrieved from https://www.sibur-int.ru/upload/basic-polymer-current-zapsibpr.pdf

- AK&M Information Agency. (2021, October 1). ZapSibNeftekhim takes over SIBUR Tobolsk. Retrieved from https://www.akm.ru/eng/news/zapsibneftekhim-takes-over-sibur-tobolsk/

- SIBUR. (2021, September 7). Tobolsk plant will double SIBUR revenue. Retrieved from https://www.sibur.ru/en/press-center/articles-interviews/tobolsk_plant_will_double_sibur_revenue/

- Hydrocarbon Engineering. (2020, December 2). Sibur ramps up ZapSibNeftekhim polyethylene plant to full capacity. Retrieved from https://www.hydrocarbonengineering.com/petrochemicals/02122020/sibur-ramps-up-zapsibneftekhim-polyethylene-plant-to-full-capacity/

- 2B1stConsulting. (2024, September 30). Sibur awards FEED contracts for ZapSibNeftekhim olefin in Tobolsk. Retrieved from https://2b1stconsulting.com/sibur-awards-feed-contracts-for-zapsibneftekhim-olefin-in-tobolsk/

- The Moscow Times. (2019, October 22). Russian petrochemical giant Sibur produces first polyethylene at new plant. Retrieved from https://www.themoscowtimes.com/2019/10/22/russian-chemical-giant-launches-production-at-siberian-plastic-plant-a67845/pdf

- Interfax. (2015, February 16). Sibur begins construction of Zapsibneftekhim in Tobolsk. Retrieved from https://interfax.com/newsroom/top-stories/37936/

- SIBUR International. (n.d.). Basic polymers product portfolio. Retrieved from http://sibur-int.com/upload/basic-polymer-current-zapsibpr.pdf