Facility Overview

Formosa Plastics Corporation's Point Comfort facility is the company's largest integrated petrochemical complex in North America, located in Point Comfort, Calhoun County, Texas on the Gulf Coast. The facility spans approximately 2,500 acres and employs nearly 2,000 people at full capacity.

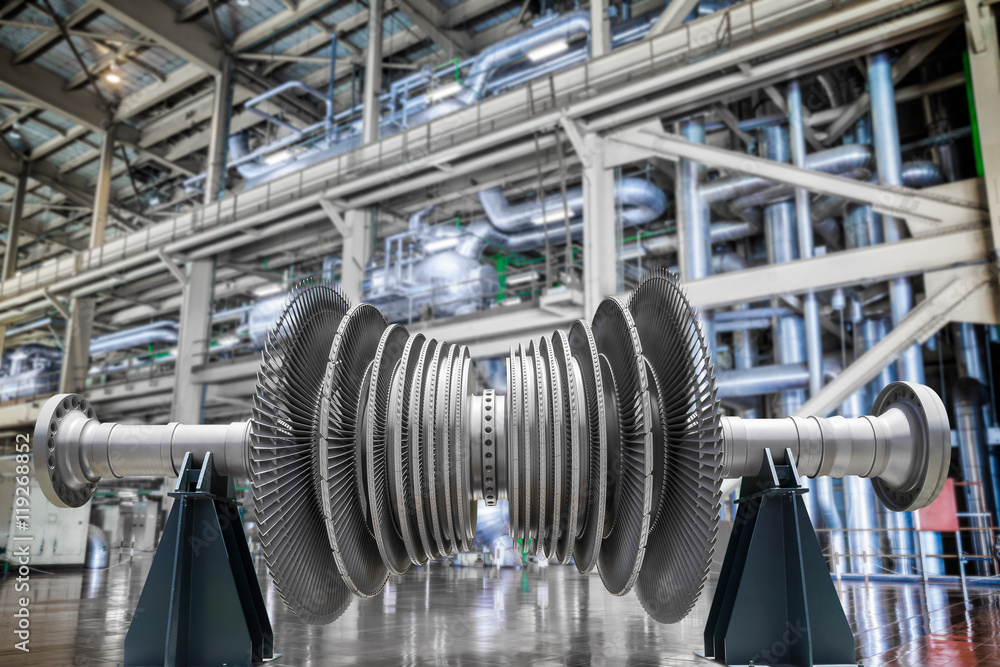

Formosa Plastics Corp. USA's Point Comfort, Texas, manufacturing complex | Credit: Formosa Plastics Corp. USA

Historical Development

1983: Original VCM/PVC plant commissioned

1990: First major expansion with olefins (OL-1)and polyethylene production

1994: Second expansion adding polypropylene capacity

2002: Second olefins plant (OL-2) completed

2012-2020: $5 billion expansion phase including Olefins 3 cracker in 2020 (OL-3), PDH unit, LDPE plant, HDPE plant, MEG-2, EO plant, and CFB cogeneration

November 2024: New polypropylene unit (250 KTA) commissioned - largest horizontal reactor in North America

November 2025: 1-Hexene plant announced - $150 million investment

Production Capacity & Output

The Point Comfort complex operates 20+ major production units representing over $5 billion in cumulative capital investment. Production capacity totals approximately 15+ million tonnes per year of petrochemicals and plastics.

Olefins Production

- Olefins 1 (OL1): 816,000 tonnes/year ethylene

- Olefins 2 (OL2): 862,000 tonnes/year ethylene (mixed-feed cracker)

- Olefins 3 (OL3): 1,250,000 tonnes/year ethylene (largest unit at facility, started January 2020)

- Propane Dehydrogenation (PDH): 600,000 tonnes/year propylene

Total Ethylene Capacity: 2.93 million tonnes/year

Polyethylene Products (1.89 million tonnes/year total)

- Low Density Polyethylene (LDPE): 625,000 tonnes/year (ExxonMobil Tubular LDPE technology)

- High Density Polyethylene (HDPE): 800,000 tonnes/year (Univation UNIPOL PE Process gas-phase technology)

- Linear Low Density Polyethylene (LLDPE): 465,000 tonnes/year (Univation technology, uses hexene comonomer)

Polypropylene (1.70 million tonnes/year total)

- PP Unit 1: Approximately 950,000 tonnes/year

- PP Unit 2: 750,000 tonnes/year including new 250,000 tonnes/year horizontal reactor commissioned November 2024 (largest in North America)

Technology: Japan Polypropylene Corporation (JPP), capable of producing full grade slate (homopolymer, random copolymer, impact copolymer)

Monoethylene Glycol (MEG) - 1.17 million tonnes/year

- MEG Unit 1: 300,000 tonnes/year (Nan Ya Plastics owned/operated)

- MEG Unit 2 (EG-2): 870,000 tonnes/year (Nan Ya owned, started 2017-2018)

- Ethylene Oxide (EO) Plant: 620,000 tonnes/year (feeds MEG production)

Chlor-Alkali & Vinyl Products

- Vinyl Chloride Monomer (VCM): 753,000 tonnes/year

- Ethylene Dichloride (EDC): 1,478,000 tonnes/year

- Polyvinyl Chloride (PVC): 955,000 tonnes/year total (855,000 suspension-grade; 100,000 specialty emulsion-grade)

- Chlorine: 910,000 tonnes/year

- Caustic Soda (NaOH): 1,000,000 tonnes/year

1-Hexene Plant (NEW)

- Capacity: 100,000 tonnes/year

- Investment: $150 million

- Status: Announced November 2025, air permits approved September 2023

- Technology: Ethylene trimerization (technology provider not publicly disclosed)

- Purpose: Produces high-purity hexene comonomer for internal polyethylene production

Energy & Utilities

Power Generation

- Circulating Fluidized Bed (CFB) Unit 1: 155 MW electric + process steam (started 2012)

- Circulating Fluidized Bed (CFB) Unit 2: 155 MW electric + process steam (started 2012)

- Fuel: Clean-burning natural gas

Total power generation capacity is 310 MW electric.

Air Separation

- ASP-1: Cryogenic air separation (general facility support)

- ASP-2: Oxygen/nitrogen production for MEG-2 plant (started 2016-2017)

Support Infrastructure

- Wastewater treatment facilities (biological and chemical treatment)

- Multiple recirculating cooling water systems

- Multi-point flare system for emergency relief and emissions control

- Extensive storage tank farms (fixed roof, floating roof, pressurized tanks)

Strategic Significance

The Point Comfort complex represents one of the most advanced integrated petrochemical sites in North America, featuring:

- Vertical Integration: Raw material processing (olefins) through finished products (polyethylene, polypropylene, PVC)

- Production Efficiency: Co-located utilities, cogeneration, and air separation optimize energy use

- Market Diversification: Multiple product lines (PE, PP, PVC, MEG, chlor-alkali) reduce market exposure

- Technology Leadership: Modern production facilities with latest process technologies and catalysts

- Capacity Strength: Approximately 15+ million tonnes/year combined production capacity

The ongoing expansion with the new 1-hexene plant demonstrates Formosa's commitment to vertical integration and self-sufficiency in critical comonomers for polyethylene production, reducing reliance on external suppliers and improving operational flexibility.