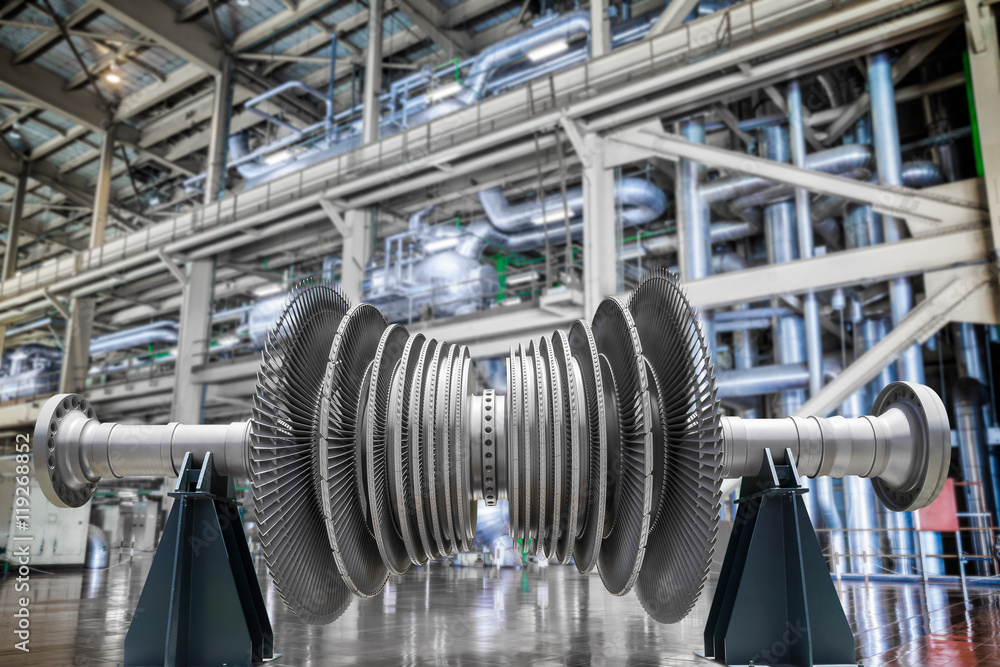

Sasol One Site | Credit: South frican Network

Sasolburg and Ekandustria Operations (SEO)

Sasolburg and Ekandustria Operations (SEO), collectively referred to as Sasolburg Operations, represents one of five Operating Hubs within Sasol South Africa Limited's Southern African Operations. Established as Sasol's founding facility in 1950, SEO encompasses an integrated chemicals manufacturing complex spanning approximately 51.4 km² across three geographically separate but operationally integrated sites: Sasol One Site, Sasol Midland Site, and Sasol Bunsen Site.

The operations transitioned from coal-based feedstock to natural gas imported from Mozambique in 2004, positioning SEO as a high-value chemicals production hub utilizing proprietary Fischer-Tropsch, chlor-alkali, and specialty chemicals technologies. SEO provides centralized utilities including steam, electricity, reformed gas, and synthesis gas to support all business units across the Sasolburg complex, ensuring operational integration and efficiency.

The facility employs state-of-the-art technologies to manufacture a diverse portfolio of base chemicals, performance chemicals, polymers, waxes, fertilizers, and mining chemicals serving domestic and international markets.

Sasol One Site Overview

Sasol One Site is the original and historic birthplace of Sasol, founded in September 1950 as South Africa's first coal-to-liquids facility. Located in Sasolburg, Free State Province, this site pioneered the commercial development of Fischer-Tropsch synthetic fuels technology and has evolved into a high-value chemicals production complex following its conversion to natural gas feedstock in 2004. The site area covers approximately 100 hectares (original plant footprint within the larger 51.4 km² SEO complex).

Primary Activities and Products

Fischer-Tropsch Hard Wax Manufacturing

- Third-generation Fischer-Tropsch Slurry Phase Distillate (SSPD) reactors

- Products: Hard wax, medium wax, liquid paraffins, and waxy oils

- Annual production capacity: ~400,000 tonnes per year (after FT Wax Expansion Project completion in 2017)

- The R13.6 billion FT Wax Expansion Project (FTWEP) doubled hard wax production capacity

- Phase 1 reached beneficial operation in September 2012

- Phase 2 reached beneficial operation in March 2017, producing an additional 116,000 tonnes annually

Ammonia Synthesis

- Production from natural gas-derived synthesis gas

- Capacity: Data not publicly disclosed

- Used as feedstock for downstream ammonium nitrate production

Ammonium Nitrate Production

- Agricultural fertilizer-grade ammonium nitrate

- Mining explosives-grade ammonium nitrate

- Integrated with ammonia plant operations

Catalyst Preparation Plant (Section 4200)

- Produces Fischer-Tropsch catalysts for Arge and SSBP (Slurry Bed) reactors

- Two distinct catalyst types manufactured:

- Arge catalyst: includes activated carbon addition

- SSBP catalyst: carbon-free formulation

- Recent expansion increased catalyst production capacity by 30%

- Proprietary iron-based catalyst technology

Ethylene Production

- Steam cracking and/or reforming processes

- Feedstock for internal downstream polyethylene plants and external sales

Phenolics Manufacturing

- Phenol and cresylic acids

- Derived from coal tar and synthesis operations

Solvents Production

- Methanol synthesis from syngas

- Various specialty solvents

Mining Chemicals

- Specialty chemicals for mining and mineral processing applications

- Integration with ammonium nitrate explosives production

Synthesis Gas Production

- Two Auto Thermal Reformer (ATR) trains commissioned in 2004

- Converts natural gas to synthesis gas (CO + H₂)

- Supplies syngas to wax plants, ammonia plant, and other chemical units

Power Generation Facilities

- Sasol Gas Engine Power Plant (SGEPP): 140 MW capacity (commissioned 2012, reached beneficial operation in 2012)

- Combined capacity with Steam Station 2: supplies steam and electricity to Sasol One and adjacent operations

- Natural gas-fired generation for lower carbon footprint

Capacities Summary

| Product/Unit |

Capacity |

Technology |

| Hard Wax |

~400,000 t/y |

Fischer-Tropsch SSPD* |

| Ammonia |

Not disclosed |

Haber-Bosch |

| Ammonium Nitrate |

Not disclosed |

Neutralization |

| Catalysts (FT) |

30% increase (2024) |

Proprietary precipitation |

| Ethylene |

Not disclosed |

Steam cracking/reforming |

| Phenolics |

Not disclosed |

Extraction/synthesis |

| Methanol/Solvents |

Not disclosed |

Syngas conversion |

| Power (SGEPP) |

140 MW |

Natural gas engines |

| Syngas (ATR) |

Two trains |

Autothermal reforming |

*Third-generation Fischer-Tropsch Slurry Phase Distillate (SSPD) reactors