Premise

The refining, gasification, and electricity cogeneration plants of ISAB S.r.l., located within the Priolo Gargallo petrochemical hub (Syracuse), represent one of the largest industrial sites in Europe, both in terms of size and complexity. The complex consists of three production sites known as the “South Plants,” “North Plants,” and the IGCC (Integrated Gasification Combined Cycle), all interconnected by a pipeline system.

The refining sector has a processing capacity of 320,000 barrels per day, a storage capacity of 4 million cubic meters of products and raw materials, and the IGCC site has an electricity production capacity of 532 MW.

Today, just over 1,000 people are employed in managing the three sites.

Processing Cycle – Refining

After the tanker docks, the unloading of raw materials begins. Through one of the pipelines, the crude oil is sent to 100,000-ton storage tanks. From there, the crude is transferred to the refining plants, where it undergoes a series of processes-such as distillation, desulfurization, and conversion-to be transformed into finished products like LPG, unleaded gasoline, kerosene, and diesel.

Since its inception, ISAB’s strength has been its technology, which is fully capable of meeting the growing demand for environmentally friendly products such as unleaded gasoline, diesel, and low-sulfur fuel oils.

The current refinery is the result of continuous evolution, with the construction of new plants and improvements to the efficiency of existing ones. This has enabled ISAB to meet market challenges, improve the quality of its products, and simultaneously reduce atmospheric pollutant emissions.

As evidence of this, the refinery and the IGCC plant have obtained certifications from independent third-party organizations, in accordance with the following international standards:

Additionally, the IGCC plant has received a Fire Prevention Certificate from the National Fire Brigade.

The two original production sites (“South Plants” and “North Plants”) differ in the type of conversion and the mix of crudes processed. The South Plants, mainly equipped with thermal conversion processes, are oriented towards the production of middle distillates and, thanks to significant desulfurization capacity, can process mainly medium-heavy, high-sulfur crudes.

The North Plants, on the other hand, are equipped with catalytic conversion and are structured to produce higher yields of light distillates, using a balanced mix of medium-heavy and light crudes.

As the most recently established refinery in Italy, ISAB handles 90% of raw materials and petroleum products via three jetties: one in the Bay of Santa Panagia, about 3 km from the South Plants, and two others-the “Superpetroliere” and “Liquids” jetties-located within the North Plants, in the port complex of Augusta. These modern infrastructures consist of arms onto which platforms are mounted for docking tankers from 1,000 to 600,000 tonnes.

Each platform is equipped with several loading arms, depending on the type of product to be transferred. The management of these arms, during all loading and unloading operations, is entirely controlled remotely, minimizing operator risk.

All three jetties are equipped with terminals for system monitoring, allowing simultaneous management of loading and unloading operations for raw materials and the full range of petroleum products, from LPG to fuel oils. The jetties are connected to the refinery’s tank farm via pipelines.

Gasification and Electricity Cogeneration

The IGCC Thermoelectric Power Plant produces electricity through a 532 MW power station that uses as fuel the gas obtained from the gasification of residues from crude processing in the refining plants.

The IGCC project was developed to minimize the environmental impact of the ISAB industrial site. Even starting from a very heavy feedstock with high concentrations of sulfur, metals, and asphaltenes, the technologies used in the plant are able to almost entirely eliminate impacts on air, water, and soil, achieving values well below the strictest limits imposed by Italian and European regulations.

The gasification plant allows the use of one million tonnes per year of heavy residues (asphalts) generated by the refining plants, transforming them into synthesis gas from which sulfur and other components are extracted.

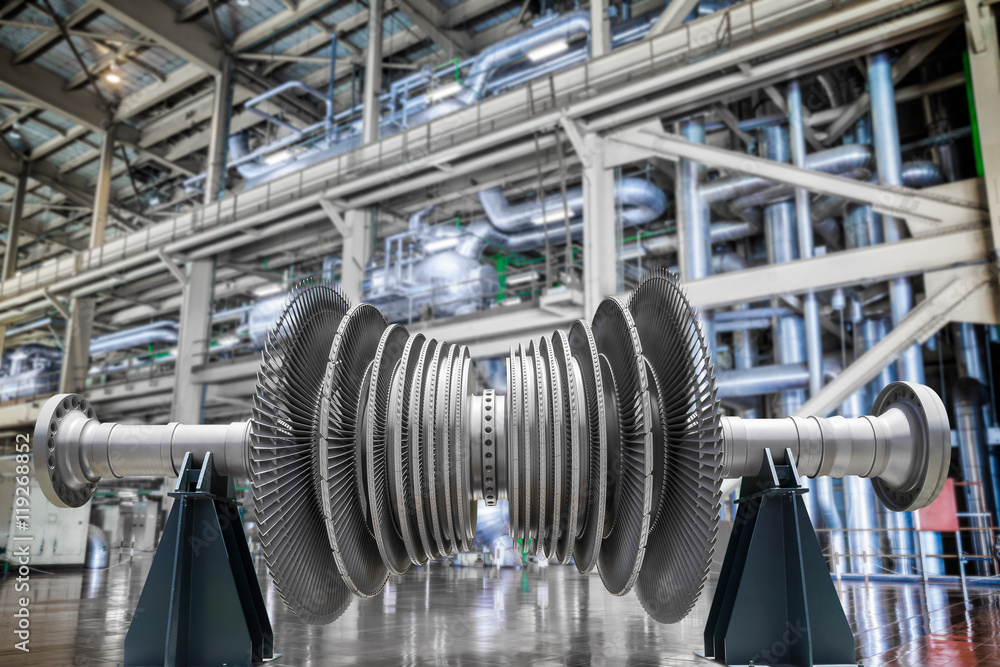

The purified gas is then sent to a combined cycle turbine system for the production of electricity and steam.

The plant produces about 4 TWh per year, representing 2% of national electricity production.

Starting from June 2010, a plant for the production of hydrogen from synthesis gas entered commercial operation. The hydrogen produced by this plant, with a capacity of approximately 20,000 Nm³/h, is sent to the refining units, where it is used for desulfurization processes.